Induction bolt heating

The process and benefits

"Our technicians understand the process and the need for selecting the correct wand and making the required machine adjustments to suit each bolt. This reduces unbolting/bolting times and heat soak into the casings."

JPG uses induction heating for precise and localised heat transfer for a faster and safer method of loosening/tightening nuts on large diameter bolts and studs. Using induction heating for bolt expansion is safer and greatly reduces the time required compared to the traditional inefficient flame and resistance heating rods. This proven method can saves days on outages meaning plant can be back online earlier reducing downtime and costs. JPG carries are large selection of wands to fit all common heated studs/bolts.

- Rapidly heat the part you want reducing heat soak into surrounding areas

- Safer - No flame or red hot rods to burn personel or components

- Greatly reduces outage times

- Reduces potential to damage threads or bolts

- Proven/reliable equipment technology

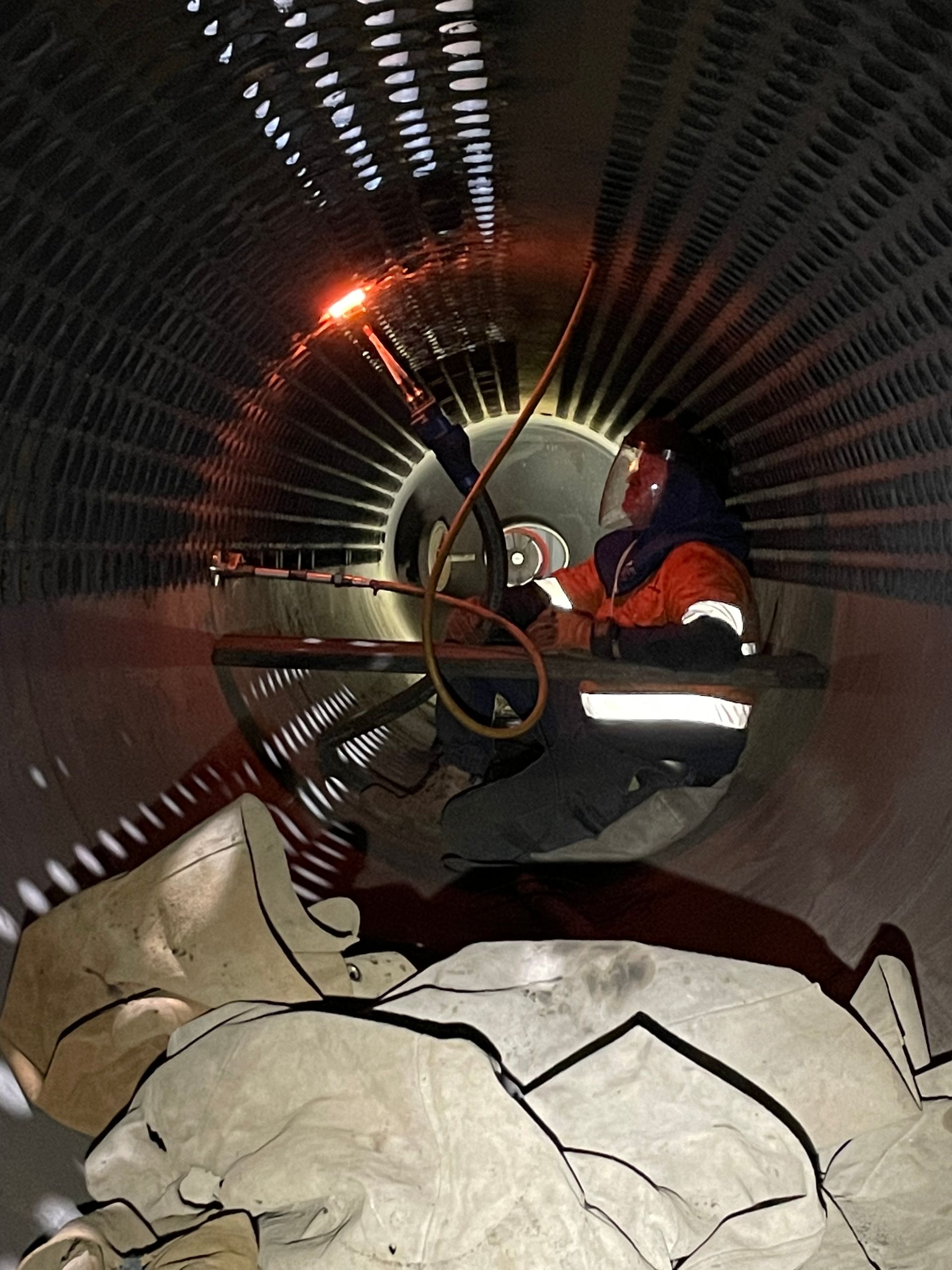

Generator retaining ring removal

The process and benefits

JPG uses specially designed thermos-flex water cooled cables in various lengths to heat generator retaining rings for removal. The diameter of the retaining rings determines the number of coils/machines required. Typically temperatures towards 300 degrees Celsius can be achieved within in an hour. With this fast heat transfer, heat soak into the rotor body is minimal making retaining ring removal easy. JPG records temperatures in multiple locations to ensure uniform heating of retaining rings.

- Time saving, both retaining historically removed in one shift

- Uniform continuous and temperature recorded heating

- Safe, easy to setup adjust equipment

- Use of insulated cables and super wool eliminate possibility of cables coming into with retaining rings and damaging them.

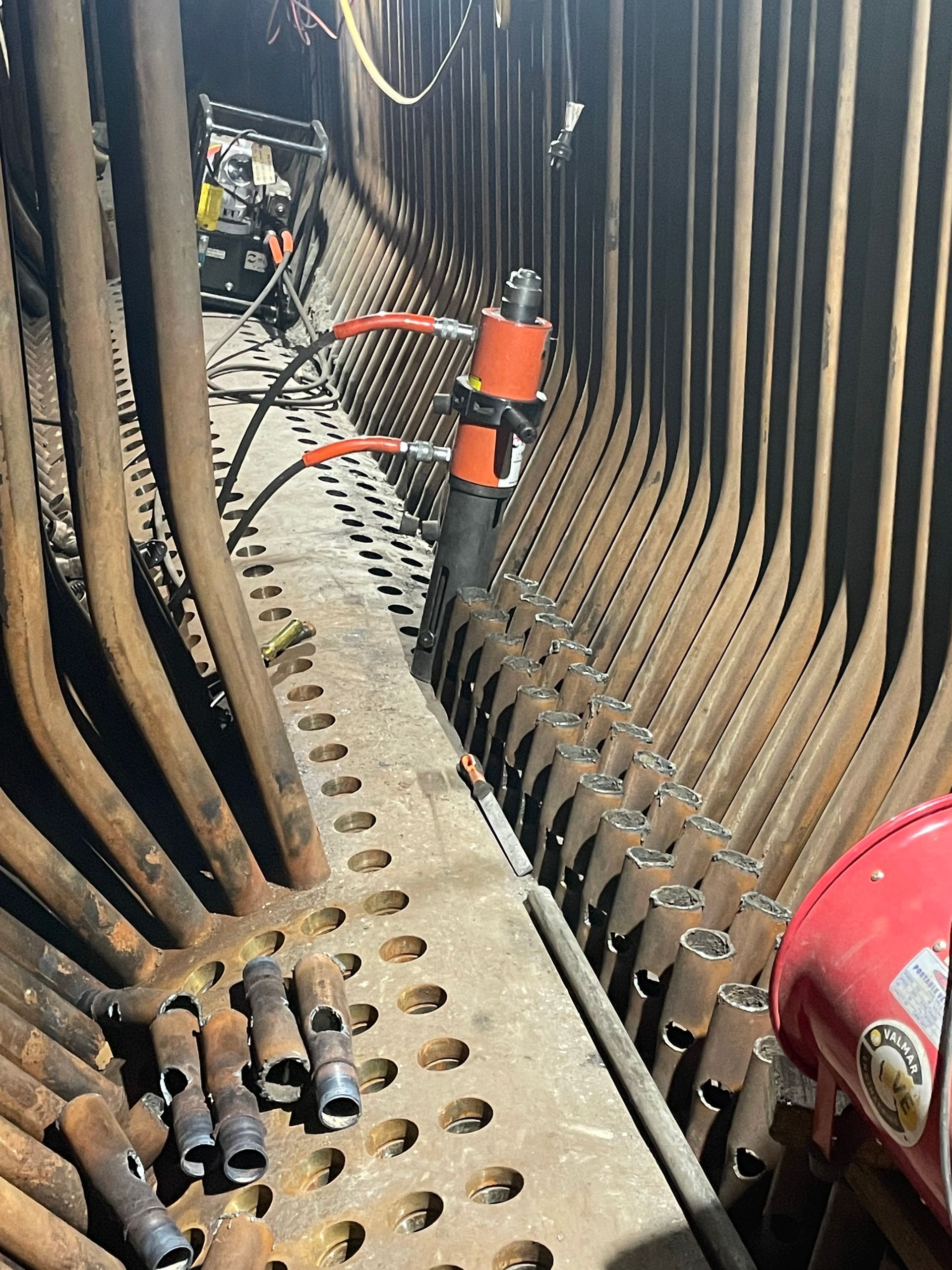

Boiler drum tube stub removal

The process and benefits

JPG uses induction heating to assist in the removal of boiler drum tube stubs. This process heats the stub where it is expanded into the tube sheet to a red-hot malleable state. Depending on the drum plate thickness, it can either be rapidly cooled to loosen the stub allowing it to be easily removed or a hydraulic stub puller used to remove the stub. This process minimises the possibility of damage to the drum tube sheet unlike the traditional methods using carbon arc gauging or gas torch splitting. JPG has now removed 3000+ tube stubs with no damage to the tube plate.

- Reduced cost and schedule for project

- Improved quality, no tube sheet repairs, easily cleaned ready for new tube installation

- Safer, reduced risks with no gas torches/arc gaugers used. Cleaner and less equipment required.